ATS Servo In-die Tapping Units & Controllers

ATS has been designing and building Servo Driven Tapping units for over 10 years with one goal in mind, to be the fastest most durable user-friendly Servo in-die tapping unit on the market today. We constantly strive for perfection. As our latest S-100 SP1 Controller combined with our Servo tapping units will demonstrate. Our controllers are designed to run with all presses from basic mechanical presses to the latest state of the art servo presses. ATS’ controller is typically a closed loop system with optional grayscale/SSI or press signal input. This gives us the ability to run with any press or as a stand-alone unit. The controller is designed to be the most user friendly available. By following the press speed automatically, the tapping unit keeps in perfect time with the press. Our menu oriented system allows programs to be created in a matter of minutes and changes to be made while the press is running to fine tune the program for optimum performance. Our Servo design allows us to utilize the largest window of time in the press cycle, which provides the fastest strokes per minute rates possible while increasing tap life. These features make ATS’ servo units most suited for tapping today’s high strength alloy steels.

S-100 SERVO CONTROLLER

BILINGUAL OPTIONS

The following features will demonstrate why ATS has no equal in the industry:

- MOST POWERFUL MOTORS AND MOTOR DRIVES

This combination of motor and drive allows for fastest rapids and strokes per minute rates. - SINGLE POINT CONNECTION

Eliminates multiple connections to the die. - DIE AND PRESS DETECTION

Has the ability to validate the job number in the press controller matches the job number in the ATS controller.

PROGRAM STORAGE

Stores up to 500 programs.

LOAD MONITORING

The controller can be set to high and low load limits to detect broken, dull or chipped taps.

STROKE COUNTER

The controller can be set to a pre-determined number of strokes for scheduled tap changes.

AIR CLAMP

The controller activates and deactivates the ATS’ air clamp system. This will assure perfect timing with the press.

CLOSED LOOP SYSTEM

The servo controller is designed to follow the press by an absolute encoder. An ATS’ exclusive.

TAP SENSOR

The Tap Sensors are wired in the controller to sense for broken taps and eliminate untapped parts. In multiple tapped holes the controller will tell the operator which tap is broken. The controller will also shut the press down when sensing a broken tap.

REMOTE CONTROL BOX

A small remote control box can be positioned anywhere on the press for the press operator’s convenience.

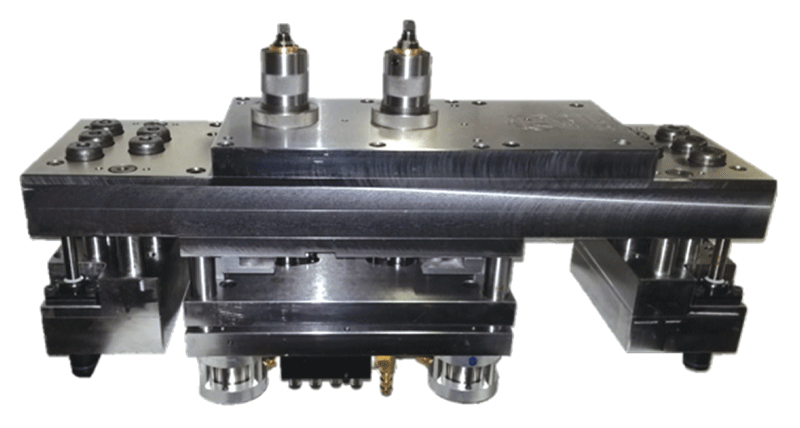

2 SPINDLE SERVO DRIVEN IDT UNIT WITH AIR CLAMP

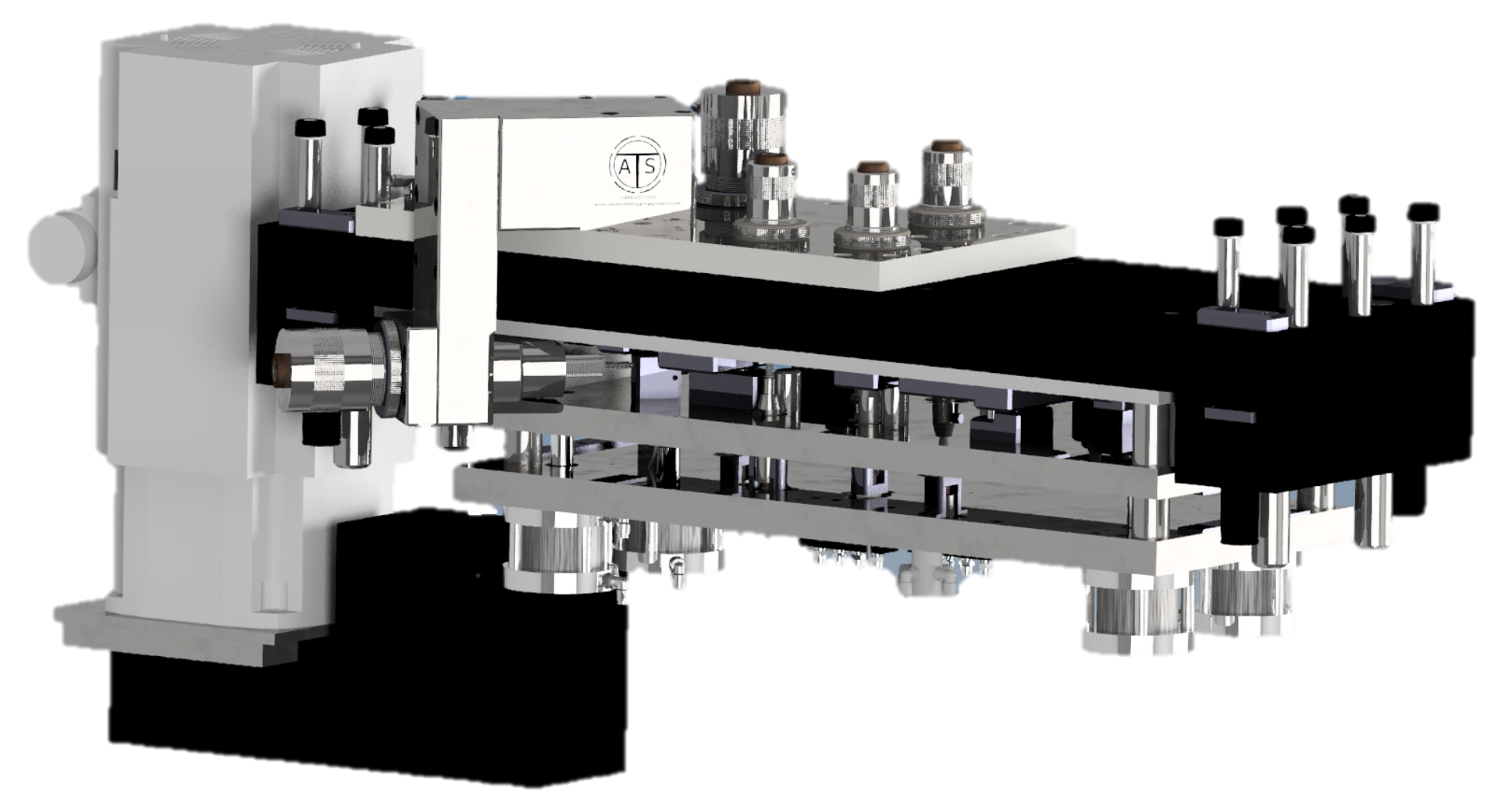

SV-65 5 SPINDLE WITH A SINGLE HORIZONTAL TAP

Each ATS’ servo controller comes with on site start up and training.

All ATS’ In Die Tapping units are furnished with unit specific BOM.

Complete 2 and 3D data is provided with every ATS’ IDT unit.

ATS offers a complimentary die design review with every IDT unit.